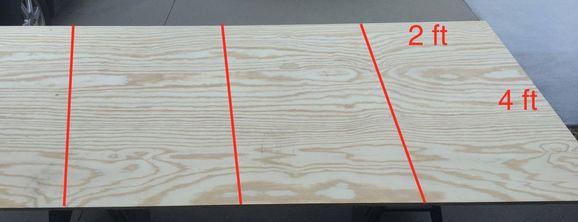

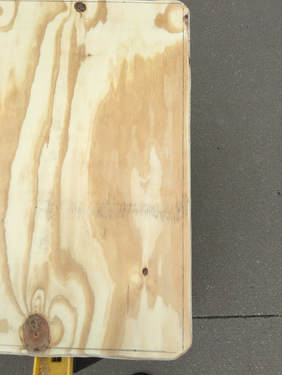

Flexible SeatingI have long been wanting to change the seating within my classroom. I preach about student choice within the classroom, but I still assign seats for students. While I do provide flexibility where student may work during independent work time, I have yet to provide more autonomy for student seating. I have a vision to completely revamp my classroom for this school year. I want to ditch the desks and create a variety of seating choices within my classroom. I want all of the seating options to have dry erase tops and be on wheels for easy reconfiguration. Below is the first part of this classroom redesign. Standing DesksAs I started to brainstorm standing desks, I gave myself a budget of $20 per desk. This was ambitious, but I wanted to keep the cost low so others could see this as an attainable option for flexible seating. Supplies: 5/8" 4 ft x 8 ft Plywood sanded (Lowes) $19 *This makes 4 table tops with 2 ft. x 4 ft dimensions 2" x 4" 8ft stud $3/each *Need two per table 1" x 2" 8ft furring strips $1/each *Need three per table 2" Lockable Caster $2.47/each *Need 4 per table (Menards) (I had to order these online) T-Nut *Still waiting for my casters to arrive to determine exact size Wood Glue Wood Filler Finishing Nails 2 1/2" Wood Screws Step 1 Cut the plywood into four pieces measuring 2 ft x 4 ft. Step 2 Round the edge of each corner. I used a spray can lid to trace and cut each corner. Step 3 Use a router around the edges. Make sure to do both sides of the board to round off the edges. Step 4 Measure 1/2" in from each side and draw lines Step 5 Cut your furring strips to edge your board. The edge of the furring strips will go against your drawn lines so that you have the 1/2" buffer between the furring strip and edge of the plywood. Run a bead of wood glue and clamp the furring strips to the sheet of plywood. I used a finishing nailer and put between four and six nails in the long sides and around three in the short sides. *My long sides were roughly 47" *My short sides were roughly 21 1/2" Step 6 Cut your 2 x 4 to length. I cut mine at 37". The caster is around 2" and my goal was to have the table top right at 40". After cutting four pieces to length, trace the 2 x 4 on each corner of the table top. After tracing in each corner, I predrilled two holes where each 2 x 4 would sit. I then ran the 2 1/2" wood screws up from the bottom so the tip was just coming through the plywood. I then put a bead of wood glue where I had traced, set the 2 x 4 in place and then screwed the screw in from underneath. **This is with the top of the table resting on the saw horses (facing the ground) and the bottom of the table facing up. Step 7 After the 2 x 4 legs are attached in each corner, I then cut a furring strip 15 1/2" long and put 45 degree cuts on each end. I put some wood glue on the furring strip and used the finish nailer to attach one end into the furring strip edge of the table and the other end into the 2 x 4 leg. Step 8 Next, I cut a furring strip piece to go horizontally across between my two angled furring strip pieces. I added some wood glue and used the finish nailer to attach. This provided stability to the legs so they wouldn't move front to back. Step 9 Set the table upright and add wood filler to the top holes that were created from the screws and finishing nails. Next StepsI am in the process of letting the wood filler dry so I can sand it. Once I get it all sanded, I will be painting the top with dry erase paint. It is roughly $20 and says it can do coats on around 55 sq. ft. I am figuring one box of dry erase paint for four tables.

I am still waiting on my casters to show up. Once they arrive, I will be installing them and then painting the legs on the tables. Once I have them completed, I will make sure to post about it. Final thoughts on cost for one table. 2 ft x 4 ft cut plywood: $5 1" x 2" furring strip x 3 @ $1/each: $3 2' x 4' 8 ft x 3 @ $3/each: $6 Dry erase paint: $5 Casters x 4 @ $2.50/each: $10 Tee nut: $0.20/each x 4: $0.80 Total Cost Per Table: $29.80

0 Comments

|

Andrew FenstermakerInstructional Technology Coordinator | Innovation Coach | Google Certified Innovator | Presenter | Blogger | Adjunct @UiowaEducation | Owner @kids_f_i_r_s_t |

RSS Feed

RSS Feed